Introduction to Bottle Molding Machines

Overview of Bottle Molding Machines

Bottle molding machines, leveraging blow molding technology, have revolutionized the manufacturing of plastic bottles across various industries. These machines are essential in producing bottles for beverages, pharmaceuticals, cosmetics, and household products. The process involves shaping plastic into hollow forms by inflating it against the contours of a mold.

Understanding Blow Molding Technology

Blow molding is a versatile manufacturing process that includes three primary types: extrusion blow molding (EBM), injection blow molding (IBM), and stretch blow molding (SBM). Each type has unique advantages and applications, making blow molding a preferred choice for bottle production.

Types of Blow Molding Processes in Bottle Manufacturing

Types of Blow Molding Processes in Bottle Manufacturing

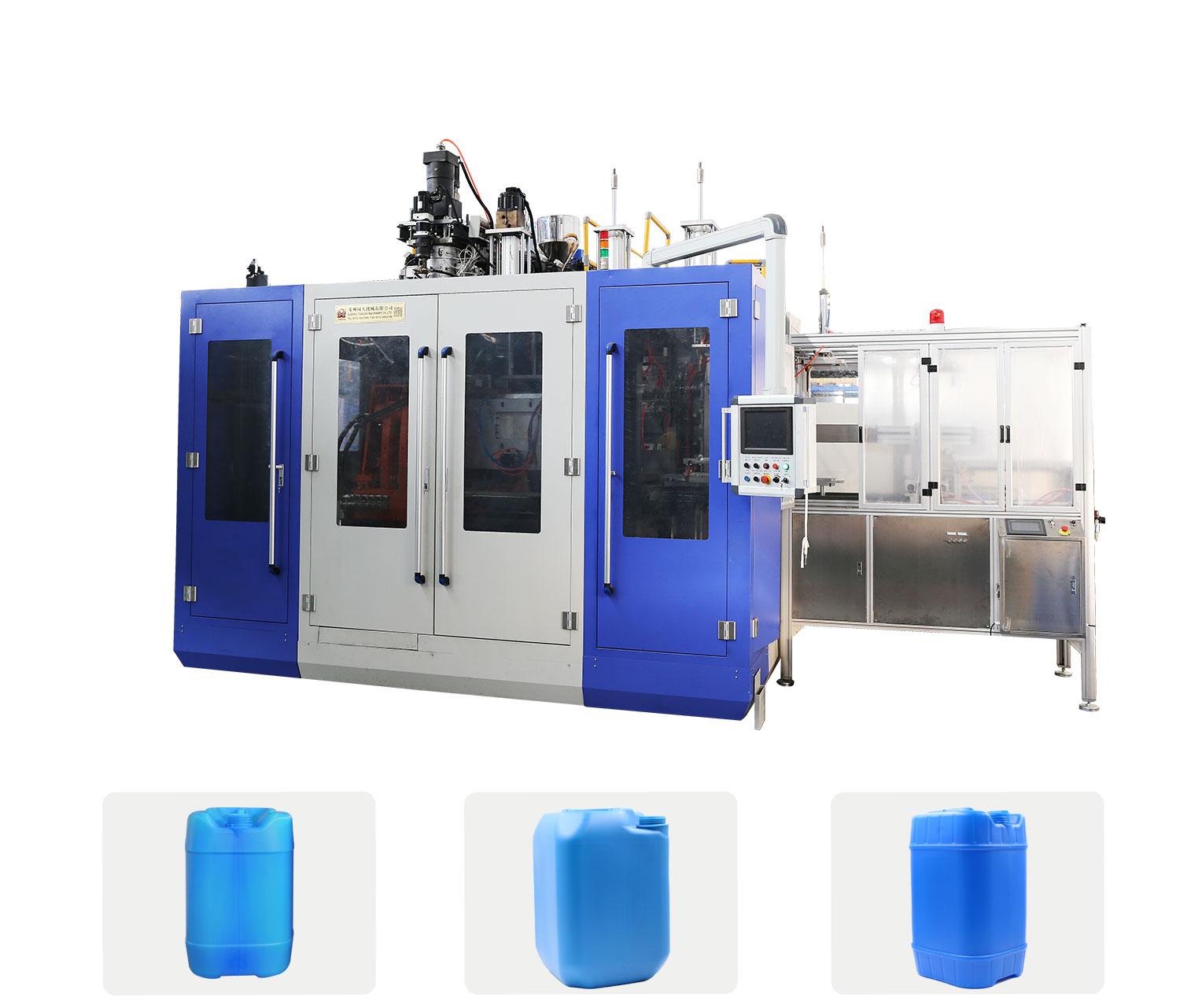

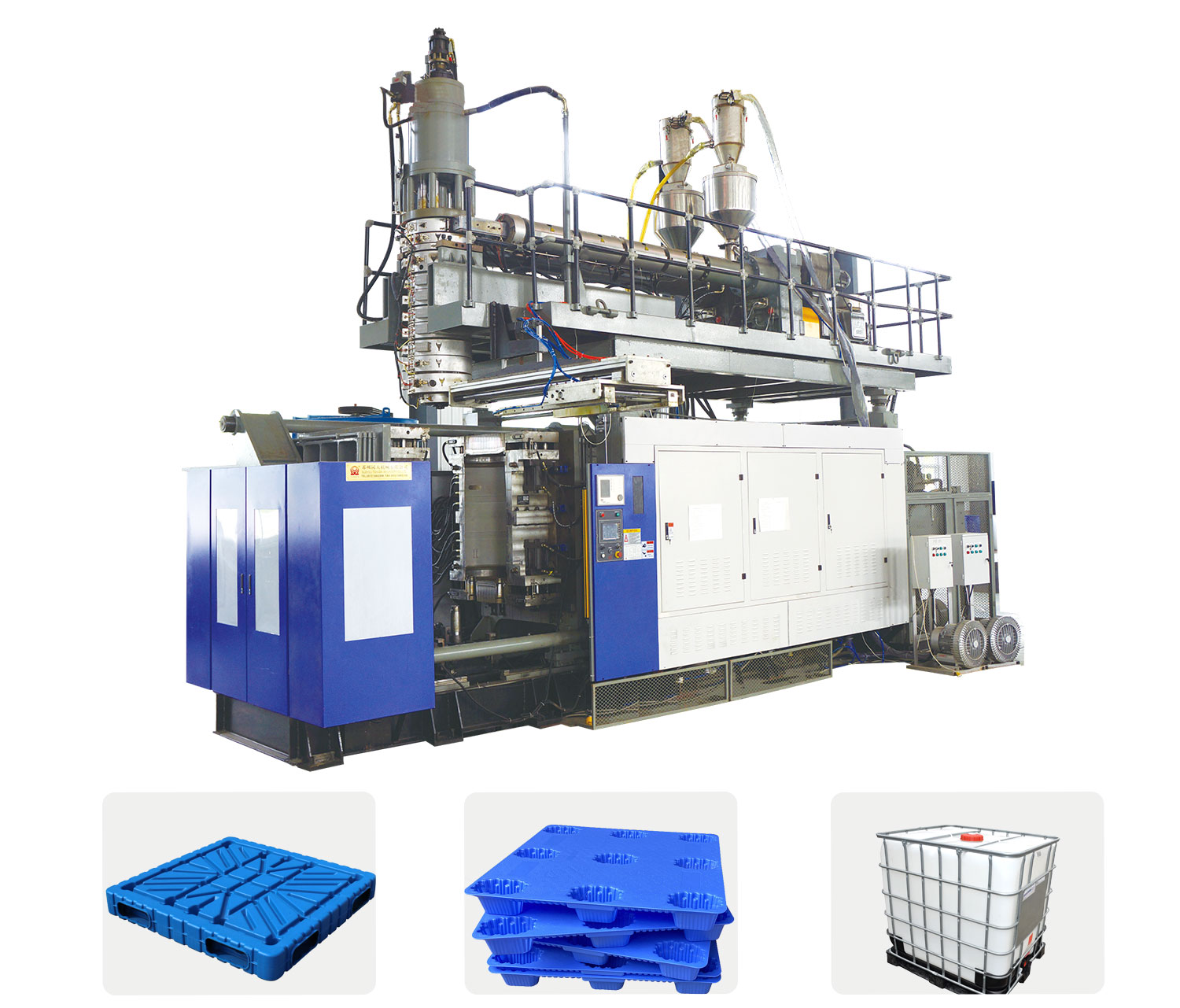

- Process: In EBM, molten plastic is extruded into a parison (a tube-like piece of plastic with a hole in one end). The parison is then clamped into a mold, and air is blown into it, inflating the plastic to match the mold’s shape.

- Applications: Commonly used for manufacturing large and small bottles, such as those used for dairy products, household cleaners, and industrial containers.

- Advantages: EBM is cost-effective for high-volume production and allows for the creation of complex shapes.

Injection Blow Molding (IBM)

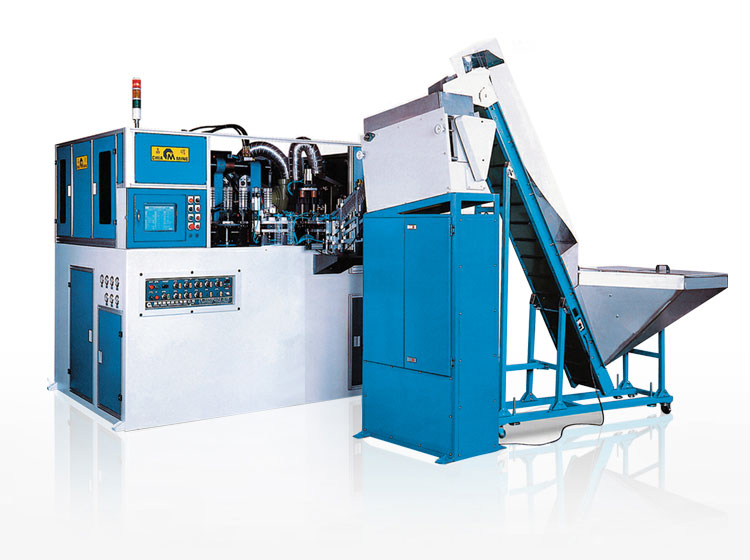

- Process: IBM involves injecting molten plastic into a preform mold to create a preform, which is then transferred to a blow mold. Air is blown into the preform, expanding it into the final bottle shape.

- Applications: Ideal for making small bottles, especially for pharmaceuticals and cosmetics.

- Advantages: Provides precise control over wall thickness and produces high-quality, uniform bottles.

Stretch Blow Molding (SBM)

- Process: SBM starts with a preform created via injection molding. The preform is heated, stretched vertically, and then blown into a mold. This biaxial stretching enhances the bottle’s strength.

- Applications: Widely used for producing PET bottles for beverages like water, soft drinks, and juices.

- Advantages: Produces lightweight, durable bottles with excellent clarity and barrier properties.

Materials Used in Bottle Molding

Different plastics are used in bottle molding, each offering distinct properties:

- PET (Polyethylene Terephthalate): Common for beverage bottles due to its strength, clarity, and recyclability.

- HDPE (High-Density Polyethylene): Used for milk jugs and detergent bottles due to its durability and resistance to chemicals.

- PP (Polypropylene): Preferred for pharmaceutical and cosmetic containers because of its resistance to heat and chemicals.

- PVC (Polyvinyl Chloride): Used for specialty bottles requiring chemical resistance and flexibility.

Design and Engineering Considerations

Designing bottles for blow molding involves several critical factors:

- Wall Thickness: Uniform wall thickness is essential for bottle integrity and performance.

- Shape and Size: Bottle design must consider the product it will hold, ease of use, and aesthetics.

- Neck Finish: The neck design impacts the capping process and overall bottle functionality.

- Material Selection: Choosing the right material based on the bottle’s application and required properties.

Quality Control in Bottle Molding

Ensuring the quality of molded bottles involves rigorous testing and inspection:

- Visual Inspection: Identifying defects like warping, bubbles, or inconsistencies in color.

- Dimensional Checks: Verifying that bottles meet specified dimensions and tolerances.

- Mechanical Testing: Assessing the bottle’s strength, drop resistance, and stress crack resistance.

- Leak Testing: Ensuring the bottle’s seal integrity to prevent leaks.

Energy Efficiency and Sustainability

Modern bottle molding machines incorporate energy-efficient technologies and sustainable practices:

- Energy Recovery Systems: Capturing and reusing heat generated during the molding process.

- Lightweighting: Reducing material use while maintaining bottle strength and functionality.

- Recyclable Materials: Using materials that are easy to recycle and incorporate recycled content into production.

Maintenance and Troubleshooting

Regular maintenance and timely troubleshooting are vital for optimal machine performance:

- Preventive Maintenance: Routine inspections and part replacements to prevent breakdowns.

- Common Issues: Addressing problems like uneven wall thickness, improper sealing, and mold wear.

- Calibration: Regular calibration ensures machine precision and product quality.